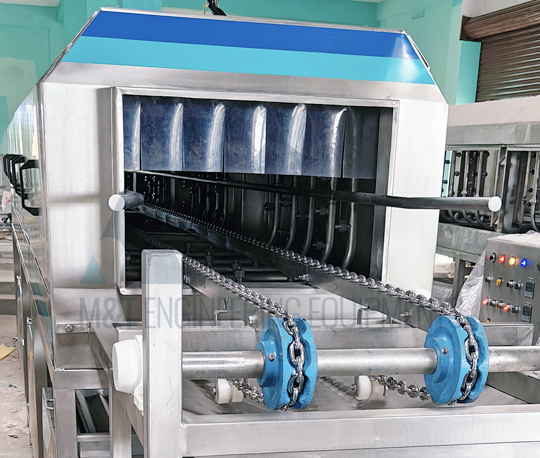

Overall, a chicken tray or meat tray washer provides an efficient and effective solution for cleaning and sanitizing trays used in the meat processing industry, helping to maintain hygiene standards, prolong the lifespan of the trays, and ensure the safety of the meat products transported or stored in them.

About Us

M&T Engineering Equipments is a pioneer manufacturer of Dairy, Pharma, and all types of Food Processing Equipment in India.